The most common definition of outsource manufacturing is when the manufacturing that one company needs performed is hired out to a different company that is ultimately responsible for the manufacturing. The manufacturing work is to an outside source which is where this term originates. Many companies participate in outsource manufacturing because of reduced production costs that are made possible through economies of scale which is a theory that holds that as a company grows and produces more goods or provides more services, their costs will probably decrease and economic growth will be achieved. Read More…

Hankscraft Inc. offers customers the ability to have all of their manufacturing needs in one supplier. With our extensive and expanding list of capabilities Hankscraft has the most comprehensive manufacturing capabilities available for our customers. We offer US manufacturing, China manufacturing or a combination of both utilizing low cost components while adding US assembly content.

Here at New Standard Corporation, we take great pride in our position as a leading provider of contract manufacturing solutions, offering a comprehensive range of products, services, and capabilities to address the diverse needs of our valued clients. With our unwavering commitment to excellence and extensive expertise in contract manufacturing, we stand ready to deliver innovative solutions that ...

PEKO Precision Products is an innovative twenty-first century contract manufacturer, with a vast set of capabilities and an expansive facility in Rochester, NY. Since PEKO’s founding in 1966 it has been providing crucial specialty manufacturing services to its customers, from sheet metal fabrication to piece part production, all the while investing in new technology and product development.

At Cretex Medical RMS, we specialize in delivering high-precision contract manufacturing solutions to the medical device industry. With decades of experience behind us, we’ve built a reputation for excellence in machining complex components and assemblies that meet the stringent demands of surgical and diagnostic applications. Our team works closely with OEMs to support every phase of the...

At AccraFab, some of our many capabilities include contract manufacturing, rapid prototyping, contract assembly and finishing. Our skilled machine operators can laser cut, punch, stamp, weld, form, assemble and package all the various types of metals we use: stainless steel, copper, aluminum and more.

More Outsource Manufacturing

While there are many kinds of manufacturing processes, there are also many different subcontractors willing to perform outsourced work. Whether it is milling, etching or welding, companies in North America or around the world are willing to accept the contract. Outsource manufacturing is widely used by many companies including those in need of aerospace, automotive, construction, electronics, food and beverage, marine, medical and pharmaceutical contract manufacturing.

Outsource manufacturing usually follows a standard business model. A company decides that it is going to hire an outside company to provide certain manufacturing services. It solicits job estimates from various companies in that business. Usually these companies are exclusively subcontractors that do outsourced work. They provide the hiring firm with bids based on the labor, tooling and material costs. The hiring firm then makes a selection based on what they interpret is the best service and the most cost effective.

Companies that outsource their manufacturing work have chosen not to purchase or rent their own production facility in order to take advantage of possible cost savings while avoiding the hassles and responsibilities of manufacturing themselves. The two companies discuss details such as the length of the contract, the amount paid and the specific manufacturing services to be provided and, once in agreement, sign a contract.

Other options beyond outsource manufacturing includes subcontract machining, contract assembly or manufacturing for a specific industry, such as aerospace, chemical or pharmaceutical plants. Hiring manufacturing services is also similar to working with an OEM, an original equipment manufacturer. OEMs fabricate products that are purchased by the hiring firm and sold under the branding of that same company. In both cases, the firm that is hired to do the actual work is not the same firm who designs, advertises, retails and profits from the services.

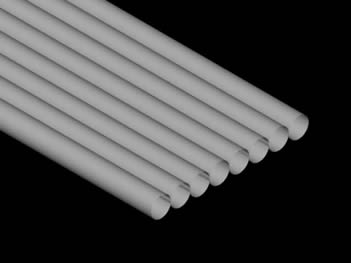

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

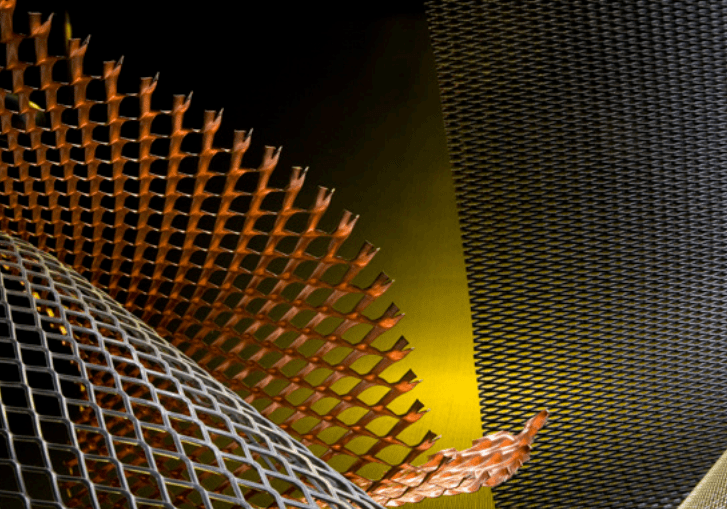

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

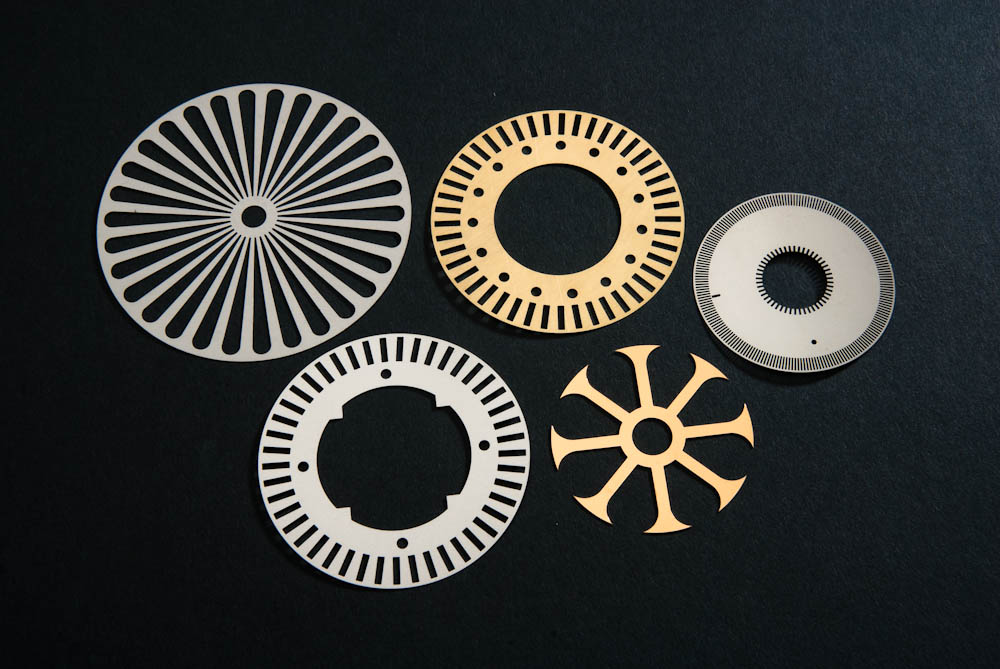

Laser Cutting Metal Etching

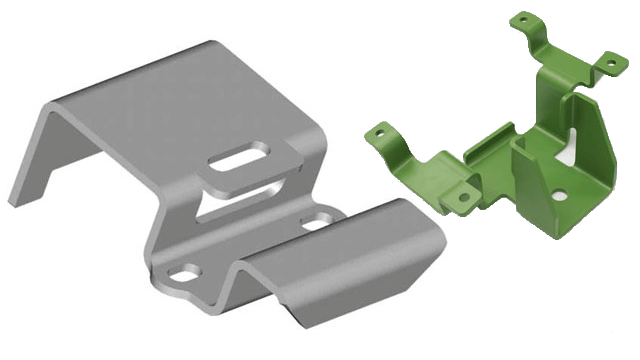

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

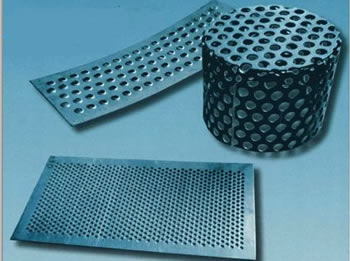

Metal Stampings Perforated Metals

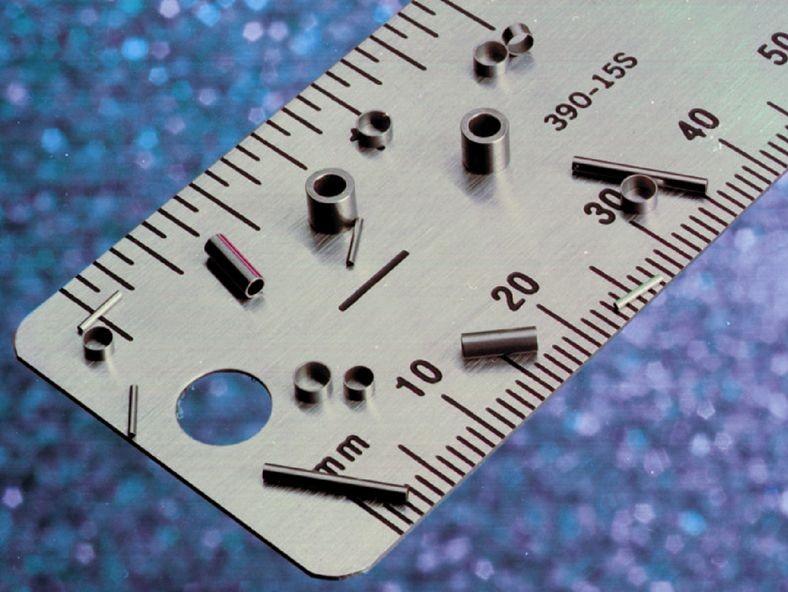

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services