The term contract manufacturing is used to describe a situation in which the needs of one company, business or client are met by hiring another company under contract. The arrangement may also be referred to as subcontracting or outsourcing because the work that is done comes from another source. Many governments or security forces take part in military contract machining because it is easier to hire an existing manufacturing facility than it is to build one and hire and train a workforce to produce the military products. Read More…

At Hankscraft we produce high-quality electromechanical assemblies and products. With our decades of contract manufacturing experience, we have many products and capabilities available to our customers worldwide.

Here at New Standard Corporation, we take great pride in our position as a leading provider of contract manufacturing solutions, offering a comprehensive range of products, services, and capabilities to address the diverse needs of our valued clients. With our unwavering commitment to excellence and extensive expertise in contract manufacturing, we stand ready to deliver innovative solutions that ...

PEKO Precision Products is an innovative twenty-first century contract manufacturer, with a vast set of capabilities and an expansive facility in Rochester, NY. Since PEKO’s founding in 1966 it has been providing crucial specialty manufacturing services to its customers, from sheet metal fabrication to piece part production, all the while investing in new technology and product development.

At Cretex Medical RMS, we specialize in delivering high-precision contract manufacturing solutions to the medical device industry. With decades of experience behind us, we’ve built a reputation for excellence in machining complex components and assemblies that meet the stringent demands of surgical and diagnostic applications. Our team works closely with OEMs to support every phase of the...

At AccraFab, some of our many capabilities include contract manufacturing, rapid prototyping, contract assembly and finishing. Our skilled machine operators can laser cut, punch, stamp, weld, form, assemble and package all the various types of metals we use: stainless steel, copper, aluminum and more.

More Military Contract Manufacturing

Military contract manufacturers come from many kinds of industries including the aerospace manufacturing sector. These firms rely on vendors, suppliers and manufacturers for parts, supplies, software, computers, electrical components and other items necessary to build the machines or vehicles. In fact, they hired companies may hire a subcontractor for specialty parts or sizes.

There is a large variety of products made through military contract manufacturing ranging from vehicles, aircraft, weapons, shelters, body armor and other equipment. Many products are made from stainless steel, iron or other metals such as tanks, guns, helmets, rocket shells, rocket bodies, barbed wire, helicopters and much more.

Before the manufacturing process even begins, the company interested in hiring a subcontractor requests bids from various contract manufacturers. Usually this "company" is a government because military supplies and products are not available to the general public. The client chooses from among the bids and job estimates from the interested manufacturers and they discuss the details of the contract.

Some manufacturing contracts are measured by units of time and last for a few years while others are measured by the output, such as the number of hummers or fight planes that are manufactured. Some military subcontractors may be involved in major structural assembly for large projects while others perform the finishing processes necessary to prepare the part for another contract manufacturer; military contract manufacturing companies do not necessarily make products from the first to the last step but rather the components and materials are made in segments and passed from one company to the next. In this way, contract manufacturers can be very specialized.

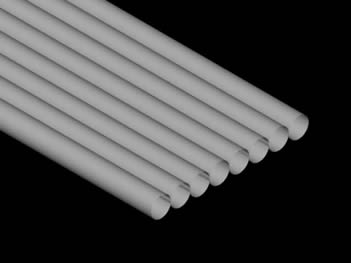

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

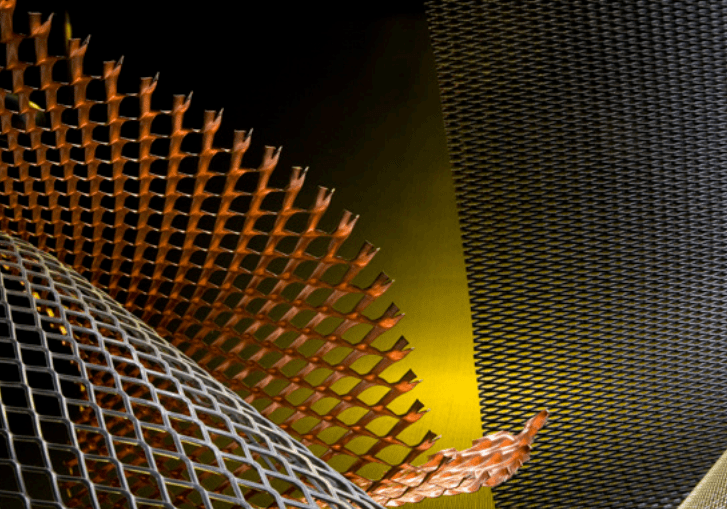

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

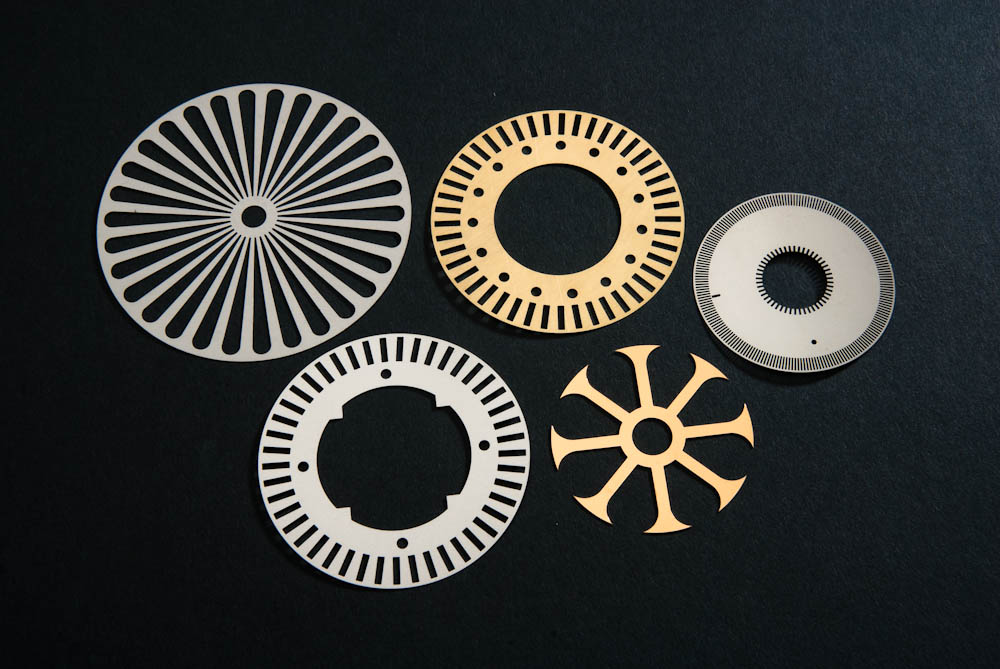

Laser Cutting Metal Etching

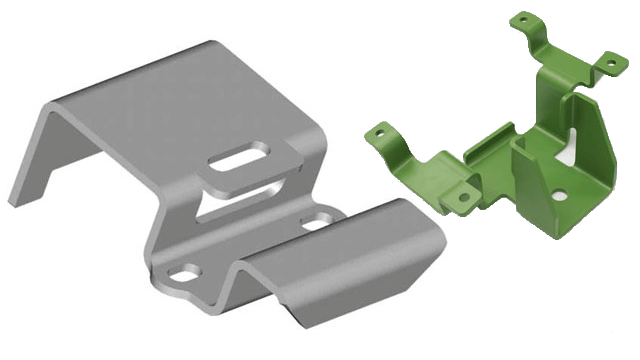

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

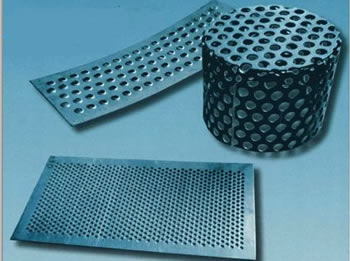

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

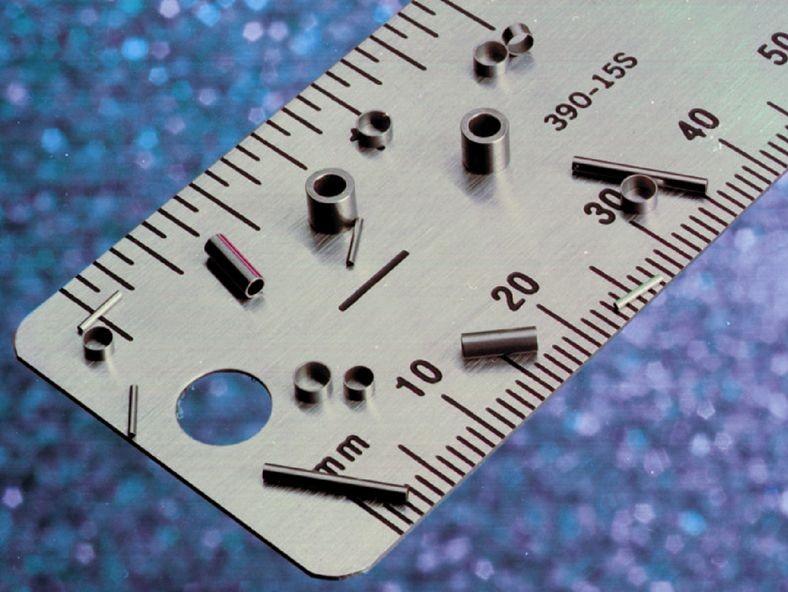

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services