Alloy Suppliers

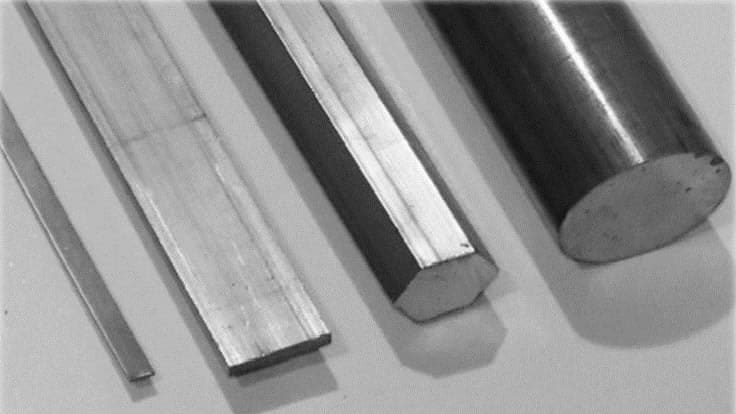

Aluminum

Aluminum Extrusions

Copper-Brass-Bronze

Magnets

Nickel

Stainless Steel

Stainless Steel Tubing

Steel Service Centers

Titanium

Tungsten

Wire Rope

How to Select a Reputable Metal Supplier for Your Business

Choosing a reputable metal supplier is a critical decision for businesses in industries like manufacturing, construction, aerospace, and automotive. The right supplier ensures you receive high-quality materials, on-time deliveries, and reliable support, while a poor choice can lead to delays, defects, and increased costs. Here’s a step-by-step guide to help you select a trusted metal supplier that meets your needs.

1. Assess Their Industry Experience and Reputation

A reputable metal supplier should have a proven track record in your industry. Look for suppliers with years of experience, as they’re more likely to understand your specific requirements, such as precision metal components for aerospace or stainless steel for medical applications. Check online reviews, testimonials, and case studies on their website to gauge their reputation. For example, companies like VACCO Industries, with over 70 years in photo etching, demonstrate reliability through their long history and client success stories.

2. Verify Certifications and Quality Standards

Quality is non-negotiable when sourcing metals. Ensure the supplier adheres to industry standards like ISO 9001, AS9100, or IATF 16949, which are common in industries requiring precision. These certifications indicate a commitment to consistent quality and compliance. For instance, a supplier offering photo etched metal parts should provide documentation of material traceability and quality control processes, ensuring the metals meet your specifications.

3. Evaluate Material Range and Customization Capabilities

A good metal supplier should offer a wide range of materials, such as stainless steel, titanium, aluminum, and copper alloys, to suit diverse applications. Additionally, check if they provide custom metal fabrication services, like cutting, etching, or forming, to meet your exact needs. Suppliers like Advanced Metal Etching, known for their hybrid etch-laser process, offer customization that can save you time and reduce the need for multiple vendors.

4. Confirm Production Capacity and Lead Times

Your supplier must be able to handle your order volume, whether it’s a small prototype run or high-volume production. Ask about their production capacity and lead times to ensure they can meet your deadlines. A reputable supplier will also have contingency plans to manage supply chain disruptions. For example, Photo Etch Technology emphasizes fast turnaround, with tooling completed in hours and parts shipped within days, which is crucial for time-sensitive projects.

5. Check for Value-Added Services

Beyond supplying raw materials, a top metal supplier should offer value-added services like precision machining, surface finishing, or assembly. These services streamline your production process and reduce costs. For instance, VACCO Industries provides diffusion bonding and laser cutting alongside photo etching, making them a one-stop shop for complex metal components.

6. Investigate Their Supply Chain and Sourcing Practices

A reliable supplier should have a robust supply chain and ethical sourcing practices. Ask where their metals are sourced and whether they can provide material certifications to verify authenticity and quality. Suppliers with strong relationships with mills, like Great Lakes Engineering, ensure consistent material availability and quality, reducing the risk of delays.

7. Evaluate Customer Service and Support

Excellent customer service is a hallmark of a reputable metal supplier. They should offer fast quotations, technical support, and responsive communication. Test their responsiveness by requesting a quote or asking technical questions about metal grades or fabrication processes. A supplier like Qualitetch, known for rapid design iterations, demonstrates the kind of support purchasing agents need for smooth procurement.

8. Compare Pricing and Payment Terms

While cost shouldn’t be the only factor, it’s important to compare pricing among suppliers to ensure you’re getting value for your money. Look for transparency in pricing and ask about payment terms, such as bulk discounts or flexible payment schedules. A reputable supplier will balance competitive pricing with quality, avoiding suspiciously low prices that may indicate substandard materials.

9. Request Samples and Test Their Products

Before committing, request samples of their metal products to test for quality, durability, and compatibility with your applications. For example, if you need titanium parts for medical devices, ensure the supplier’s materials meet biocompatibility standards. Testing samples helps you avoid costly issues down the line and confirms the supplier’s claims about their products.

10. Look for Sustainability and Innovation

Sustainability is increasingly important in metal sourcing. Choose a supplier that prioritizes eco-friendly practices, such as recycling scrap metal or using energy-efficient processes. Additionally, look for suppliers who invest in innovation, like adopting advanced technologies for precision metal fabrication. Companies like PEI, which focus on renewable energy applications, show a commitment to both sustainability and innovation.

Partner with a Trusted Metal Supplier Today

Selecting a reputable metal supplier requires careful consideration of their experience, quality standards, capabilities, and customer service. By following these steps, you can find a partner who delivers high-quality metals and supports your business goals. Ready to source precision metal components or custom metal parts? Contact a trusted supplier today to request a quote and start building a reliable partnership.

How to Select the Best Type of Metal for Your Custom Part

Selecting the right metal for your custom metal part is crucial for ensuring performance, durability, and cost-effectiveness in industries like aerospace, automotive, medical, and electronics. With various metals available, each offering unique properties, making an informed choice can be challenging. This guide will walk you through the key factors to consider when choosing the best metal for your custom part, helping you achieve optimal results for your project.

Understand Your Part’s Application and Requirements

The first step in selecting a metal is to define the custom part’s purpose and operating conditions. Consider the following:

-

Mechanical Stress: Will the part endure heavy loads or vibrations? For high-strength applications, stainless steel or titanium may be ideal due to their excellent tensile strength.

-

Environmental Exposure: Will the part be exposed to moisture, chemicals, or extreme temperatures? Stainless steel and aluminum offer corrosion resistance, while titanium excels in high-temperature environments, as noted in its use for aerospace components by suppliers like VACCO Industries.

-

Functionality: Does the part need to conduct electricity or heat? Copper is a top choice for electrical conductivity, often used in photo etched components like lead frames for electronics.

Evaluate Material Properties

Each metal has distinct properties that affect its suitability for your custom metal part:

-

Strength and Hardness: For structural components, stainless steel (e.g., 304 or 316 grades) provides durability, while titanium offers a high strength-to-weight ratio, ideal for aerospace parts.

-

Corrosion Resistance: Aluminum and stainless steel resist rust, making them suitable for outdoor or marine applications. Titanium is also highly corrosion-resistant, often used in medical implants due to its biocompatibility.

-

Weight: If weight is a concern, aluminum is lightweight yet strong, commonly used in automotive parts to improve fuel efficiency.

-

Thermal and Electrical Conductivity: Copper and aluminum are excellent conductors, perfect for electrical components or heat exchangers, as seen in applications by Advanced Metal Etching.

Consider Manufacturing Processes

The fabrication method for your custom part can influence metal selection. For example:

-

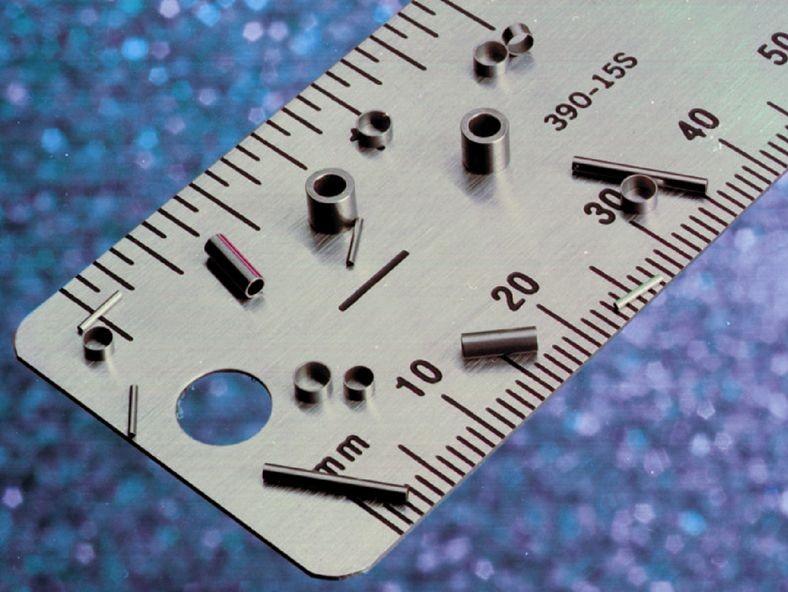

Photo Etching: If you’re using photochemical etching for precision parts, metals like stainless steel, copper, and titanium are ideal due to their compatibility with the process. Companies like PEI emphasize titanium’s suitability for etched medical components.

-

Machining or Forming: Softer metals like aluminum and brass are easier to machine, reducing production costs. Harder metals like titanium may require specialized tools but offer superior durability.

-

Welding or Joining: Stainless steel and aluminum are weldable, but titanium requires advanced techniques due to its reactivity at high temperatures.

Factor in Cost and Availability

Budget constraints play a significant role in metal selection. Aluminum and stainless steel are generally more affordable and widely available, making them cost-effective for large-scale production. Titanium and nickel alloys, while offering superior properties, are more expensive and may have longer lead times. Suppliers like Great Lakes Engineering highlight the importance of balancing cost with performance, especially for high-volume orders.

Assess Regulatory and Industry Standards

Certain industries have strict requirements for custom metal parts. For example:

-

Medical: Titanium and stainless steel are often chosen for their biocompatibility, as required for implants or surgical tools.

-

Aerospace: Titanium and aluminum meet stringent standards like AS9100 for weight, strength, and corrosion resistance.

-

Electronics: Copper and nickel alloys are selected for their conductivity and EMI shielding properties, as seen in components produced by Microphoto.

Ensure your metal supplier provides material certifications to verify compliance with standards like ASTM or ISO, ensuring your part meets regulatory requirements.

Test for Compatibility and Performance

Before finalizing your choice, request samples from your metal supplier to test the material’s performance in your application. For instance, if you’re creating a photo etched part for an electronic device, test copper for conductivity and durability under operating conditions. Suppliers like Qualitetch offer rapid prototyping, allowing you to validate your metal choice before full production.

Consult with Your Metal Supplier

A reputable metal supplier can provide expert guidance on material selection. Share your project specifications—such as tolerances, environmental conditions, and budget—with your supplier to get tailored recommendations. Companies like Photo Etch Technology, with decades of experience, can suggest the best metals for precision metal parts, ensuring your custom component meets all requirements.

Choose the Right Metal for Your Custom Part Today

Selecting the best metal for your custom part involves balancing application needs, material properties, manufacturing processes, cost, and regulatory standards. By following these steps, you can ensure your custom metal part delivers the performance and reliability your project demands. Ready to source high-quality metals for your next project? Partner with a trusted metal supplier to get started with expert support and precision manufacturing.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

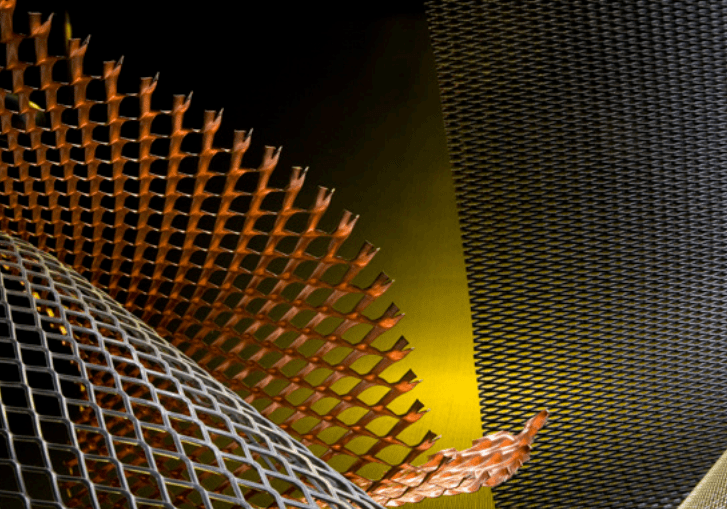

CNC Machining Expanded Metals

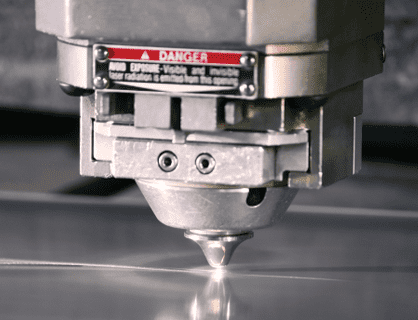

Expanded Metals Laser Cutting

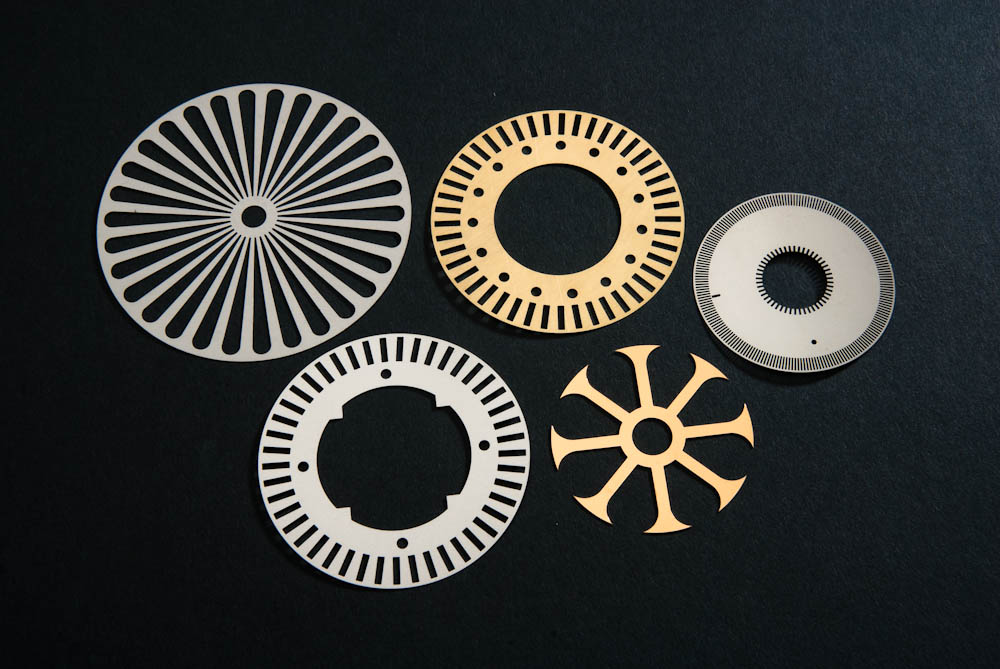

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

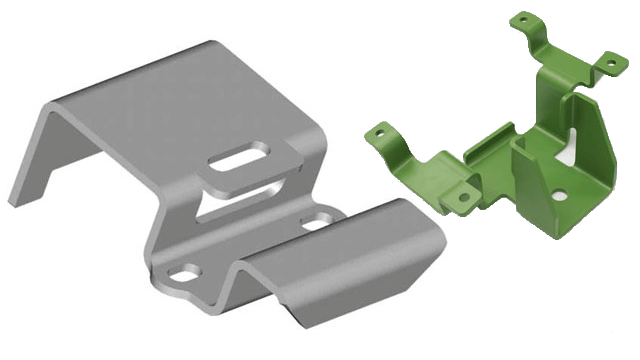

Metal Fabrication Metal Stampings

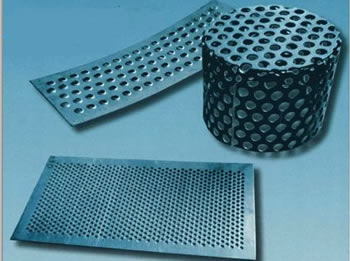

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

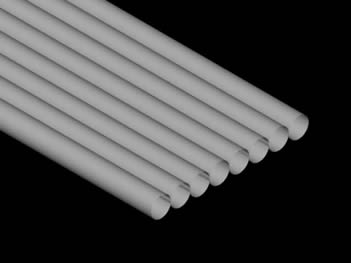

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services