Electronic contract manufacturing, also referred to as electronic manufacturing services, is a term that is used for companies that design, test, manufacture and distribute electronic components and assemblies for original equipment manufacturers (OEM). Electronic products, due to their complexity, are often contracted for manufacture. In many cases, OEMs choose to have their electronics made by another company that specializes in the product they need. Read More…

Hankscraft Inc. has been in the electronic contract manufacturing industry since 1920. We attribute our success to our high-quality products and our knowledgeable team. Our mission is to firmly understand the needs of our customers and create lasting relationships. Our experience helps us support you with design for manufacturability, and electro-mechanical assembly.

Acro Industries Inc. was founded in 1974 and specializes in contract manufacturing, sheet metal fabrication, CNC machining, and metal stamping. Throughout the entire process, we work closely with the customer to customize the design to your needs. We will also help with the supply chain management process.

At tec5USA, we present ourselves as a contract manufacturing partner committed to delivering precision, consistency, and advanced technical capability for customers developing optical, electronic, and analytical systems. We focus on supporting complex, high-performance products by combining deep engineering expertise with disciplined manufacturing processes that meet the strict standards required ...

Solidify Manufacturing has become a premier leader in the contract manufacturing industry through our hard work and dedication. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

At ALKAB Machine and Welding, we present ourselves as a contract manufacturing partner dedicated to delivering precision, durability, and dependable production support for customers across a wide range of industries. We combine advanced machining capabilities with skilled welding and fabrication expertise to produce components and assemblies that meet strict performance and quality standards.

More Electronic Contract Manufacturing

By purchasing the product through a contract manufacturer, the OEM saves money on engineering, infrastructure and assembly costs. Knowing that its electronic product will be made by a competent manufacturing facility and its labor force, the OEM is freed from the responsibilities of manufacturing and is instead able to concentrate on other aspects of its business such as distribution and marketing once the goods are completed. Industries that employ electronic contract manufacturers include information processors, industrial, medical, communication companies and consumer electronics, to name a few.

Electronic contract manufacturing is just one example of contract manufacturing. When any OEM is in need of extra assistance or is not able to complete manufacturing tasks due to facility or man power limitations contract manufacturing services are established. The hired company is considered to be outsourced, a term that can refer to a company in the same country as the hiring company or a foreign company. Often, a foreign manufacturer from a developing country is selected because of its low cost labor force.

Contracts typically last between three and five years, but can go longer or shorter depending on the product. These types of contracts are beneficial because they offer work stability for the contract manufacturer and relieve the OEM from the costs of running a facility and managing and training a work force. Typically the contract manufacturer has its own quality control and quality assurance procedures. Disadvantages of these agreements include loss of control over manufacturing for the OEM, the risk of losing intellectual property and if the contracted company is foreign language and cultural barriers and long lead times can interfere with production.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

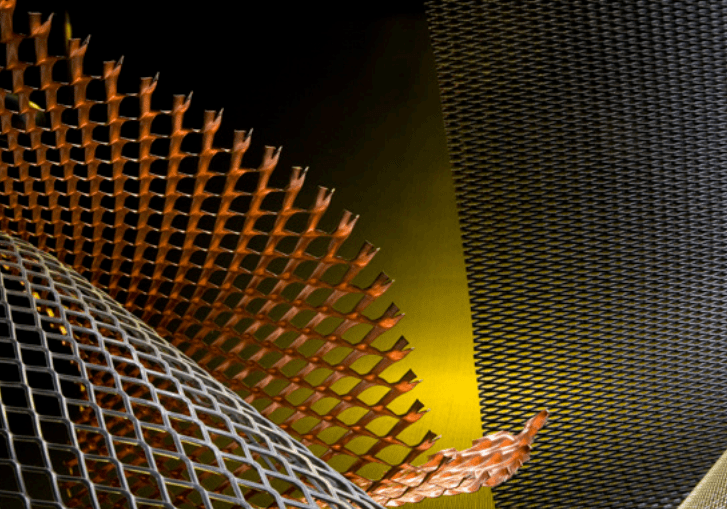

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

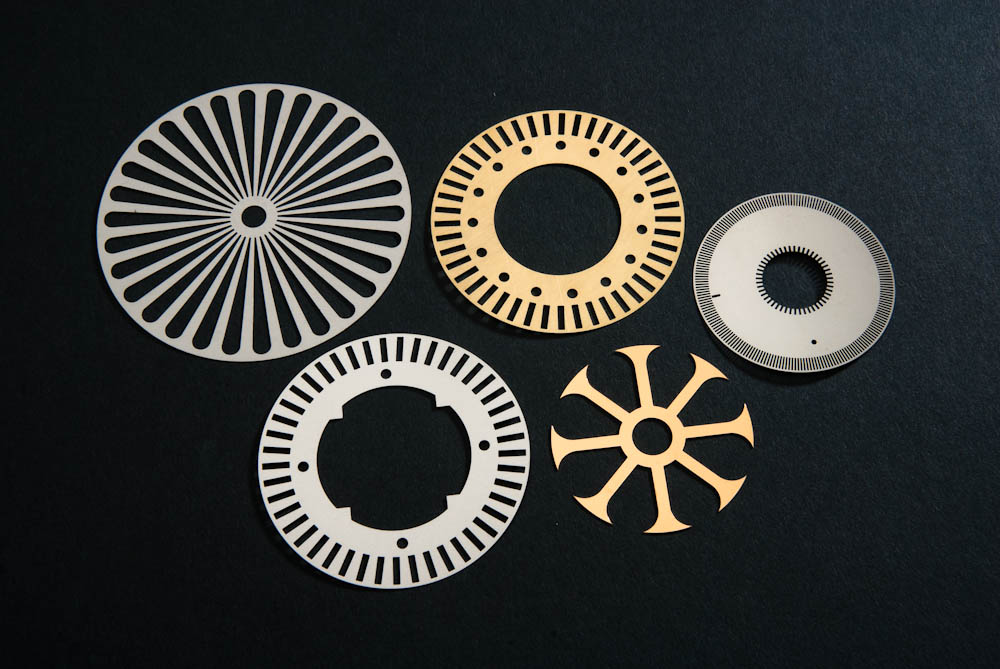

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

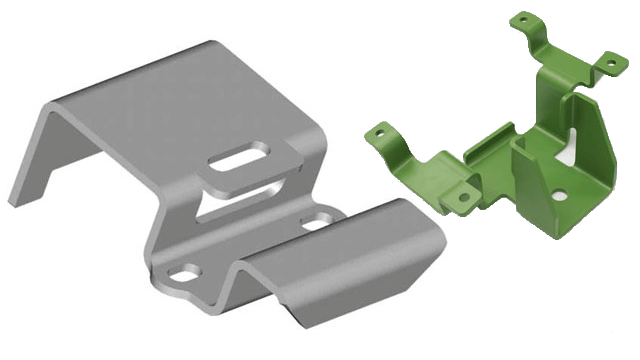

Metal Fabrication Metal Stampings

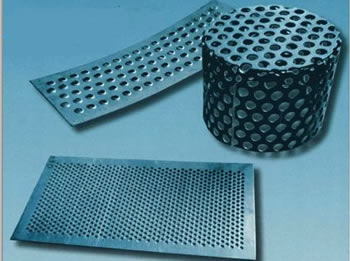

Metal Stampings Perforated Metals

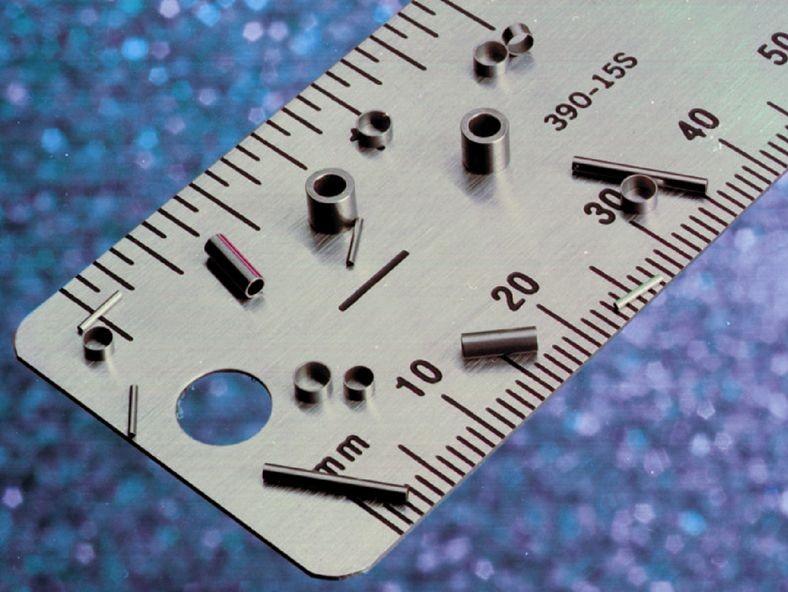

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

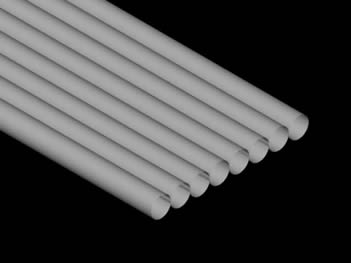

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services