In this kind of transaction, the second company is referred to as the OEM, or original equipment manufacturer. Read More…

Since 1920, Hankscraft Inc. has been a leader in the contract manufacturing industry, producing dependable and high-quality products for all of our customers. We pride ourselves on our contributions to the industry and being industry experts. From plastics, to metals, to assembly we can manage your entire program.

Here at New Standard Corporation, we take great pride in our position as a leading provider of contract manufacturing solutions, offering a comprehensive range of products, services, and capabilities to address the diverse needs of our valued clients. With our unwavering commitment to excellence and extensive expertise in contract manufacturing, we stand ready to deliver innovative solutions that ...

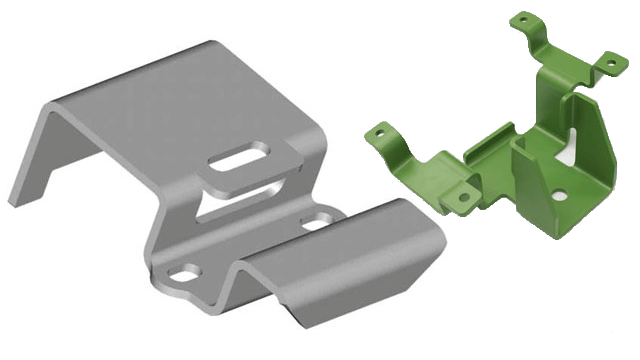

PEKO Precision Products is an innovative twenty-first century contract manufacturer, with a vast set of capabilities and an expansive facility in Rochester, NY. Since PEKO’s founding in 1966 it has been providing crucial specialty manufacturing services to its customers, from sheet metal fabrication to piece part production, all the while investing in new technology and product development.

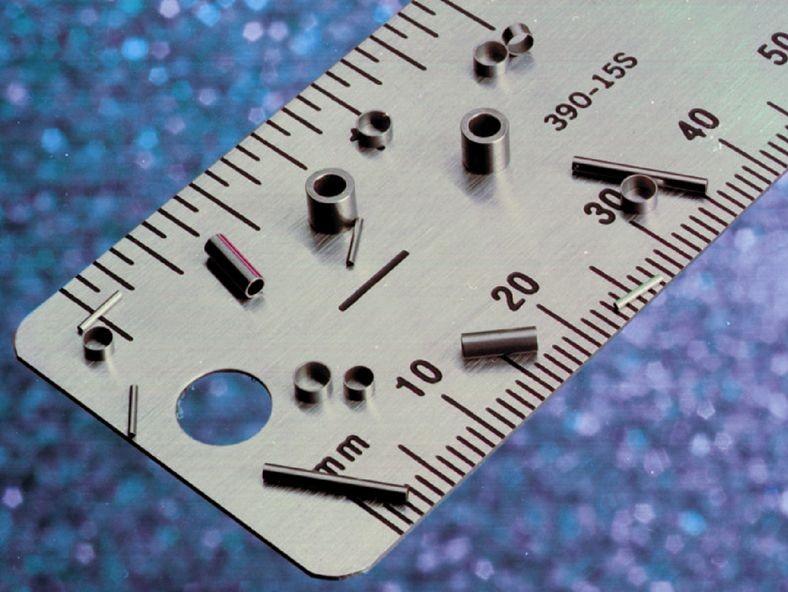

At Cretex Medical RMS, we specialize in delivering high-precision contract manufacturing solutions to the medical device industry. With decades of experience behind us, we’ve built a reputation for excellence in machining complex components and assemblies that meet the stringent demands of surgical and diagnostic applications. Our team works closely with OEMs to support every phase of the...

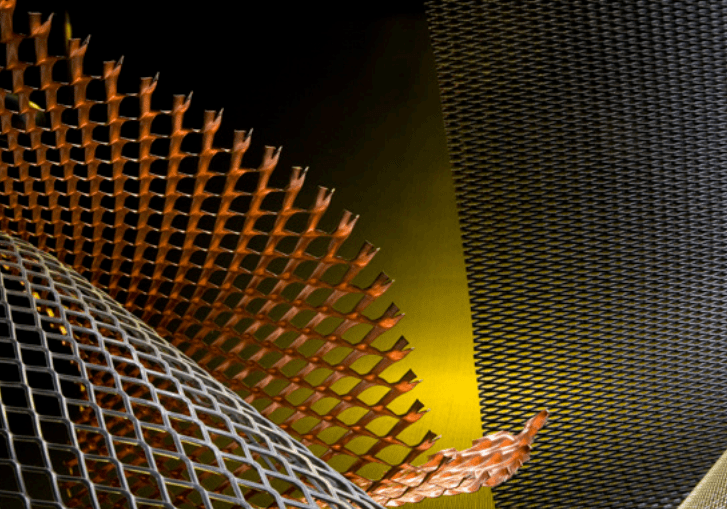

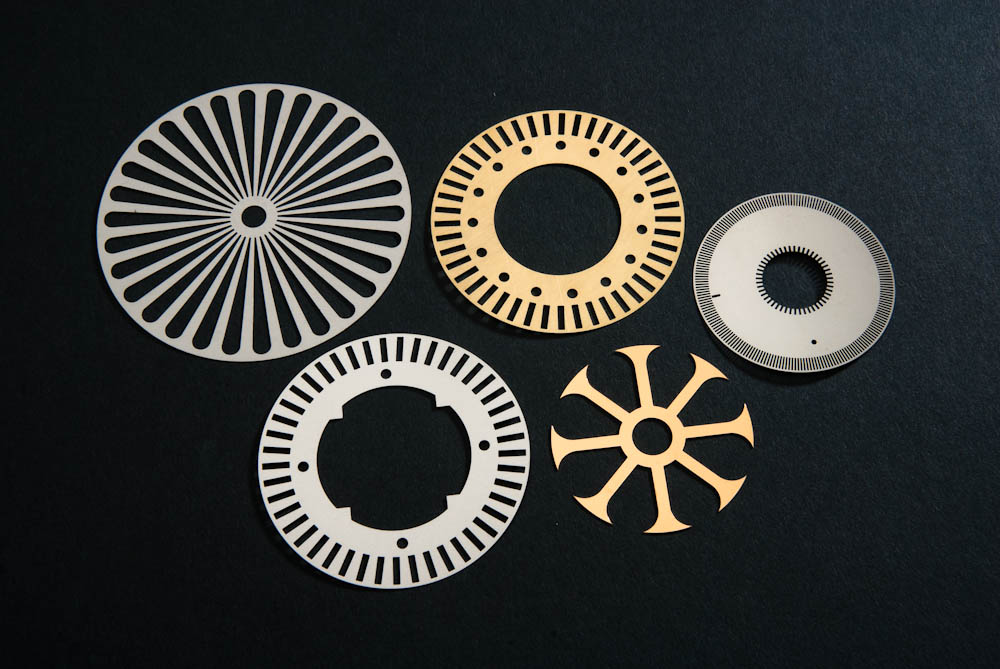

At AccraFab, some of our many capabilities include contract manufacturing, rapid prototyping, contract assembly and finishing. Our skilled machine operators can laser cut, punch, stamp, weld, form, assemble and package all the various types of metals we use: stainless steel, copper, aluminum and more.

More Contract Manufacturing Companies

Contract Manufacturing: Comprehensive Guide to Outsourced Production Solutions

Contract manufacturing plays a pivotal role in today's global supply chain, serving as a strategic solution for OEMs (Original Equipment Manufacturers) seeking efficient, scalable, and cost-effective production capabilities. This practice, often referred to as outsourcing manufacturing, allows businesses to leverage the expertise, technology, and labor of third-party manufacturers to bring products to market faster and more efficiently.

What Is Contract Manufacturing?

Contract manufacturing is a business model where one company (the hiring firm or OEM) enters into a formal agreement with another company (the contract manufacturer or CM) to produce components, sub-assemblies, or finished products. This relationship can be domestic or international, with many companies choosing to partner with foreign manufacturers to take advantage of lower labor and production costs. However, the scope of contract manufacturing services extends far beyond just offshoring; it encompasses any arrangement where an OEM relies on a third party for part or all of their manufacturing process.

Key Terms Related to Contract Manufacturing

- OEM (Original Equipment Manufacturer): The business that designs and markets the product but outsources its manufacturing.

- CM (Contract Manufacturer): The partner company that manufactures products or components on behalf of the OEM.

- Outsource Manufacturing: The practice of contracting with external parties to produce goods, either domestically or internationally.

- Turnkey Manufacturing: A full-service manufacturing solution where the contract manufacturer manages everything from sourcing materials to final assembly and quality control.

- Private Label Manufacturing: Production of goods that are branded and sold under the OEM's name, often used in consumer goods industries.

Why Do Companies Use Contract Manufacturing?

There are many compelling reasons why companies across diverse industries turn to contract manufacturing services to support their operations. Below are some of the primary drivers:

- Cost Reduction: Outsourcing eliminates the need for investment in production facilities, equipment, and labor, allowing companies to reduce operational expenses and capital expenditures.

- Access to Specialized Skills: Contract manufacturers often possess advanced manufacturing processes, technical expertise, and quality assurance systems that may not be available in-house.

- Scalability and Flexibility: Businesses can quickly scale production volumes up or down in response to market demand without the burden of managing fixed assets.

- Faster Time-to-Market: Leveraging an established manufacturer's supply chain and infrastructure can significantly shorten product development cycles and speed up market entry.

- Focus on Core Competencies: By outsourcing production, OEMs can concentrate on design, innovation, branding, and customer relationships rather than manufacturing logistics.

- Risk Mitigation: Sharing production responsibilities with a contract manufacturer can reduce supply chain risks and production downtime.

Are you considering outsourcing manufacturing for your business? Explore how to select the right contract manufacturing partner.

Industries That Rely on Contract Manufacturing

Contract manufacturing is a cornerstone in a variety of sectors, each with unique requirements and applications. Some of the most prominent industries that use contract manufacturing include:

- Aerospace & Defense: Complex assemblies, avionics, and precision machined components are frequently outsourced to meet stringent quality and regulatory standards.

- Automotive: From engine parts to electronics and interior assemblies, contract manufacturers help automotive OEMs optimize supply chains and cut costs.

- Medical Devices & Healthcare: High-precision components, surgical instruments, and diagnostic equipment are often produced by specialized FDA-compliant contract manufacturers.

- Electronics & Semiconductors: PCB assembly, microelectronics, and finished consumer electronics rely on global contract manufacturing networks.

- Consumer Goods & Appliances: Private label and turnkey production services support rapid product launches and branding initiatives.

- Energy & Industrial Equipment: Fabrication, welding, and assembly of heavy machinery and renewable energy components are commonly outsourced.

- Telecommunications: Network devices, infrastructure hardware, and enclosures are produced to meet evolving technology standards.

Looking for a contract manufacturer in your industry?

Use our industry-specific contract manufacturer directory to identify qualified partners in your sector.

Types of Contract Manufacturing Services

The field of contract manufacturing encompasses a wide range of specialized services, enabling OEMs to tailor their production strategies. Common types of contract manufacturing include:

- CNC Machining & Precision Machining: High-tolerance components for aerospace, medical, and automotive applications.

- Injection Molding & Plastic Fabrication: Production of complex plastic parts for electronics, consumer goods, and automotive.

- Die Casting (Aluminum, Zinc, Magnesium): Metal parts manufacturing for industrial, automotive, and electrical applications.

- Sheet Metal Fabrication: Stamping, bending, and cutting for enclosures, chassis, and brackets.

- Electronics Assembly (PCBA): Printed circuit board assembly, soldering, and testing for electronic devices.

- Wire Harness & Cable Assembly: Custom wiring solutions for transportation, energy, and industrial equipment.

- Box Build & System Integration: Complete product assembly, including mechanical, electrical, and software integration.

- Complex Assembly & Value-Added Services: Kitting, packaging, sub-assembly, labeling, and final product testing.

Need help determining which contract manufacturing service fits your project? Speak with a contract manufacturing consultant for guidance.

Benefits of Contract Manufacturing

Outsourcing production to experienced contract manufacturers offers a variety of strategic advantages:

- Significant Cost Savings: Eliminate the expense of maintaining production facilities, machinery, and direct labor. Benefit from the manufacturer's economies of scale and supplier relationships.

- Quality Assurance & Regulatory Compliance: Most contract manufacturers employ robust quality management systems (QMS) and adhere to international standards such as ISO 9001, ISO 13485, or AS9100.

- Access to Advanced Manufacturing Technologies: Take advantage of the latest automation, robotics, and precision engineering capabilities without upfront investment.

- Faster Product Innovation: Accelerate prototyping, design iteration, and new product introduction by leveraging the CM's engineering resources.

- Reduced Supply Chain Complexity: Simplify logistics, sourcing, and inventory management by consolidating production with a reliable partner.

- Geographic Flexibility: Tap into global networks of contract manufacturing companies to reach new markets, optimize lead times, and mitigate geopolitical risks.

- Focus on High-Value Activities: Free up internal resources to drive product development, marketing, and customer engagement.

Potential Risks and Disadvantages of Contract Manufacturing

While contract manufacturing offers many benefits, it is also important to be aware of the associated risks and challenges:

- Loss of Control: Entrusting production to a third party means less direct oversight of manufacturing processes, quality, and schedules.

- Intellectual Property (IP) Risks: Sharing proprietary designs, formulas, and technologies can expose businesses to IP theft or misuse, especially in jurisdictions with weak enforcement.

- Communication and Cultural Barriers: Working with international contract manufacturers may involve differences in language, time zones, and business practices.

- Extended Lead Times: Global supply chains can introduce delays due to shipping, customs, and unforeseen disruptions.

- Quality Variability: Not all contract manufacturers maintain the same standards. It's critical to perform due diligence and ongoing quality audits.

- Dependency on Key Suppliers: Over-reliance on a single contract manufacturer can expose your business to supply chain risks if the partner experiences disruptions.

What to Look for in a Contract Manufacturing Partner

Mitigating these risks starts with a careful selection process. When evaluating potential contract manufacturers, consider the following factors:

- Experience & Industry Expertise: Does the manufacturer have a proven track record in your product category or sector?

- Certifications & Compliance: Ensure the partner meets relevant industry certifications (e.g., ISO, FDA, ITAR) and regulatory requirements.

- Quality Management Systems: Look for robust inspection, testing, and documentation processes.

- Capacity & Scalability: Can the manufacturer handle your required volumes and adapt to future growth?

- Transparency & Communication: Clear, proactive communication channels are essential for ongoing project success.

- Location & Logistics: Consider proximity to your facilities, shipping routes, and ability to meet delivery timelines.

- Intellectual Property Protections: Strong legal agreements and confidentiality measures reduce the risk of IP theft.

Ready to start vetting contract manufacturers? Read our step-by-step guide to selecting the right partner.

Contract Manufacturing Process Overview

The contract manufacturing process typically follows a structured sequence of steps to ensure successful project execution:

- Project Scoping & RFQ (Request for Quotation): Define requirements, timelines, and specifications. Solicit quotes from multiple vendors.

- Vendor Evaluation & Selection: Assess potential partners based on technical capabilities, cost, compliance, and reputation.

- Contract Negotiation & Agreement: Establish terms related to pricing, delivery, quality standards, IP ownership, and warranties.

- Prototyping & Design Validation: Create and test prototypes to confirm manufacturability and functionality.

- Pilot Production & Process Optimization: Conduct trial runs and fine-tune processes for volume manufacturing.

- Full-Scale Production: Ramp up to mass production, with ongoing quality assurance and production monitoring.

- Logistics & Delivery: Manage inventory, packaging, shipping, and final delivery to the OEM or end customer.

- Continuous Improvement: Monitor performance, collect feedback, and implement process improvements as needed.

Common Use Cases and Applications for Contract Manufacturing

Contract manufacturing is used in a wide range of scenarios, from startups launching new products to established corporations optimizing global supply chains. Typical use cases include:

- New Product Introduction (NPI): Rapid prototyping, validation, and initial production runs to support product launches.

- Capacity Expansion: Supplementing in-house production during periods of high demand.

- Technology Transfer: Moving legacy product lines to external suppliers to free up internal resources for innovation.

- Market Diversification: Establishing production in new geographic regions to serve local markets more effectively.

- Cost Optimization: Shifting manufacturing to regions with lower labor and material costs to enhance profitability.

Not sure if contract manufacturing is right for your business model? Contact our experts for a free project assessment.

How to Find and Evaluate Contract Manufacturing Companies

If you are ready to outsource production, follow these steps to identify and qualify the best contract manufacturing companies for your needs:

- Define Your Project Requirements: Clarify product specifications, expected volumes, quality standards, and regulatory needs.

- Research Potential Partners: Use online directories, trade shows, industry associations, and referrals to compile a list of qualified manufacturers.

- Request Detailed Proposals: Solicit quotes that include pricing, lead times, capabilities, and references.

- Conduct Site Audits: Visit facilities (virtually or in-person) to evaluate production capabilities, cleanliness, and process controls.

- Check Certifications & References: Verify credentials, review case studies, and speak to existing customers.

- Negotiate Contract Terms: Outline clear terms for pricing, quality, IP protection, and exit strategies.

For a curated list of reputable contract manufacturers, search our contract manufacturing company directory.

Frequently Asked Questions About Contract Manufacturing

What is the difference between contract manufacturing and original equipment manufacturing (OEM)?

An OEM designs and owns the product while outsourcing manufacturing to a contract manufacturer. The contract manufacturer fabricates products or assemblies based on the OEM's specifications but does not own the product design.

How do I protect my intellectual property when outsourcing manufacturing?

Protect your intellectual property by using non-disclosure agreements (NDAs), robust contracts, and working with manufacturers in jurisdictions with strong IP enforcement. Regular audits and limiting access to sensitive data are also important.

What types of products are best suited for contract manufacturing?

Products that require specialized production processes, high-volume runs, tight tolerances, or regulatory compliance are ideal for contract manufacturing. Examples include medical devices, electronics, automotive parts, and consumer appliances.

How do I choose between domestic and overseas contract manufacturers?

Consider factors such as cost, lead times, quality standards, IP risk, and proximity to your target market. Domestic partners may offer greater control and shorter lead times, while overseas manufacturers often provide cost advantages for large-scale production.

What are the main costs involved in contract manufacturing?

Main costs include unit price, tooling and setup charges, shipping, customs duties, and quality control expenses. Transparent pricing structures and clear contracts help avoid hidden fees.

Conclusion: Is Contract Manufacturing Right for Your Business?

Contract manufacturing is a powerful tool for companies seeking to streamline operations, reduce costs, and accelerate product development. By leveraging the capabilities of specialized manufacturing partners, businesses can achieve greater flexibility, speed, and competitive advantage. However, successful outsourcing requires careful planning, rigorous partner selection, and ongoing management to mitigate risks and maximize benefits.

If you are ready to explore contract manufacturing solutions or want to learn more about the process, connect with our expert team today.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

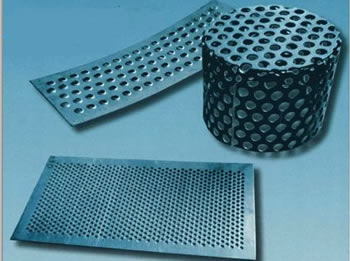

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services