Many companies take part in chemical contract machining because of reduced production costs through economies of scale. It is also easier to hire an existing chemical plant than it is to build a facility and hire, manage and train a workforce. The hired firm, or subcontractor, is usually able to provide a wide range of chemical manufacturing and synthesis processes or they may specialize in a particular type of synthetic, organic or inorganic chemical. Read More…

Hankscraft Inc. is a leading and trusted medical contract manufacturer. With our extensive background in the industry and years of experience we are a trusted manufacturer and supplier.

Here at New Standard Corporation, we take great pride in our position as a leading provider of contract manufacturing solutions, offering a comprehensive range of products, services, and capabilities to address the diverse needs of our valued clients. With our unwavering commitment to excellence and extensive expertise in contract manufacturing, we stand ready to deliver innovative solutions that ...

PEKO Precision Products is an innovative twenty-first century contract manufacturer, with a vast set of capabilities and an expansive facility in Rochester, NY. Since PEKO’s founding in 1966 it has been providing crucial specialty manufacturing services to its customers, from sheet metal fabrication to piece part production, all the while investing in new technology and product development.

At Cretex Medical RMS, we specialize in delivering high-precision contract manufacturing solutions to the medical device industry. With decades of experience behind us, we’ve built a reputation for excellence in machining complex components and assemblies that meet the stringent demands of surgical and diagnostic applications. Our team works closely with OEMs to support every phase of the...

At AccraFab, some of our many capabilities include contract manufacturing, rapid prototyping, contract assembly and finishing. Our skilled machine operators can laser cut, punch, stamp, weld, form, assemble and package all the various types of metals we use: stainless steel, copper, aluminum and more.

More Chemical Contract Manufacturing

The scientists, engineers and other technical personnel who work for chemical manufacturers are trained in such as organic chemistry, analytical chemistry, or biopolymer chemistry. Chemical contract manufacturers obtain the necessary starting materials, compounds and equipment in order to fulfill their end of the contract. Chemical contract manufacturing is widely used by practically any industry that requires chemicals for their processes, such as pharmaceutical companies, petrochemical companies, the plastics industry, waste water treatment and waste management plants.

Chemical manufacturing involves many steps and processes. The materials used may be raw or polluted and so they must be distilled and dried before they are mixed or blended with other substances. The mixture goes through purification, which may or may not occur depending on the properties of the specific chemical.

Certain components may be extracted from the chemical mixture. The product may undergo chemical synthesis in the conversion of raw materials into more usable molecules or it may go through catalysis, the process of slowing down or speed up reactions by adding a substance that will not itself be changed. For chemical manufacturing, large amounts of heat and energy are generally required. Before the manufacturing process even begins, however, the company interested in outsourcing requests quotes from various contract manufacturers.

After reviewing the job estimates from the interested companies, the hiring firm chooses one and they discuss the details of the arrangement. Usually the two companies enter into a contract of one to three years, though other lengths are often set as well. Depending on the reputation and financial stability of the companies, longer terms may be set. Chemical contract manufacturing is beneficial for both the manufacturer and the hiring company. The chemical plant is offered the guarantee of steady work and pay for the duration of the contract while the hiring firm saves on costs and stress.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

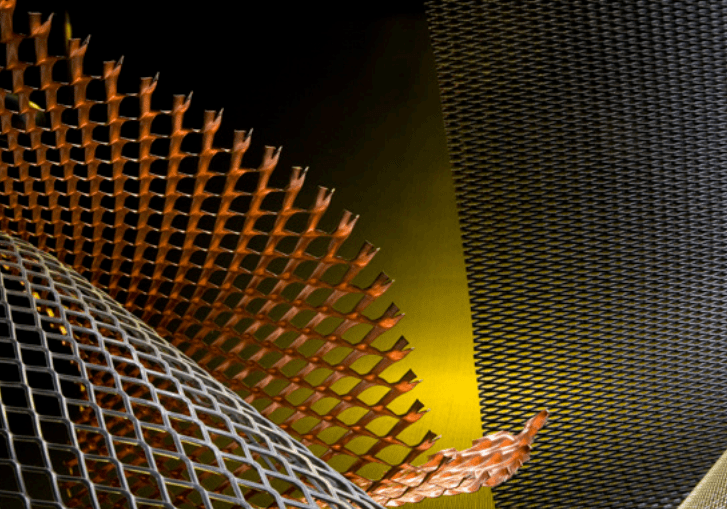

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

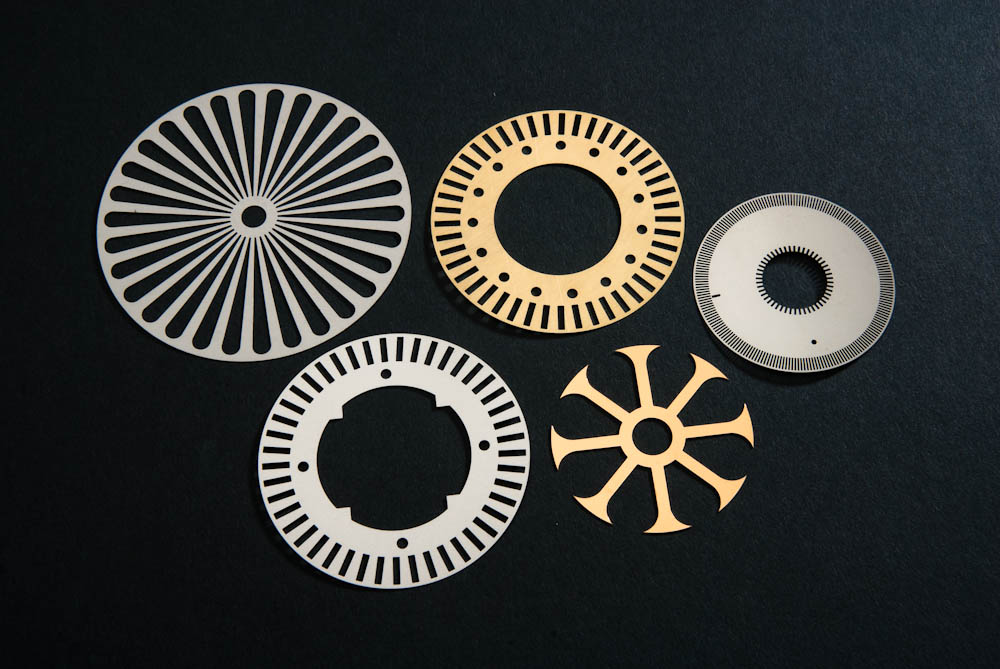

Laser Cutting Metal Etching

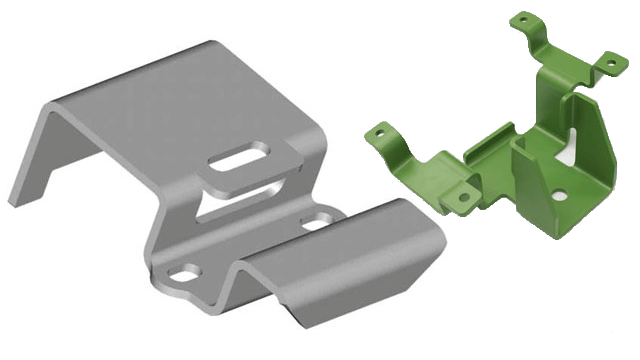

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

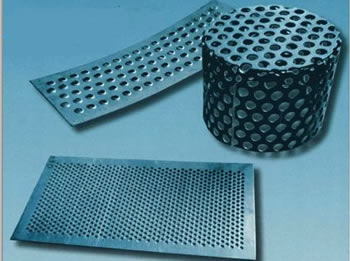

Metal Stampings Perforated Metals

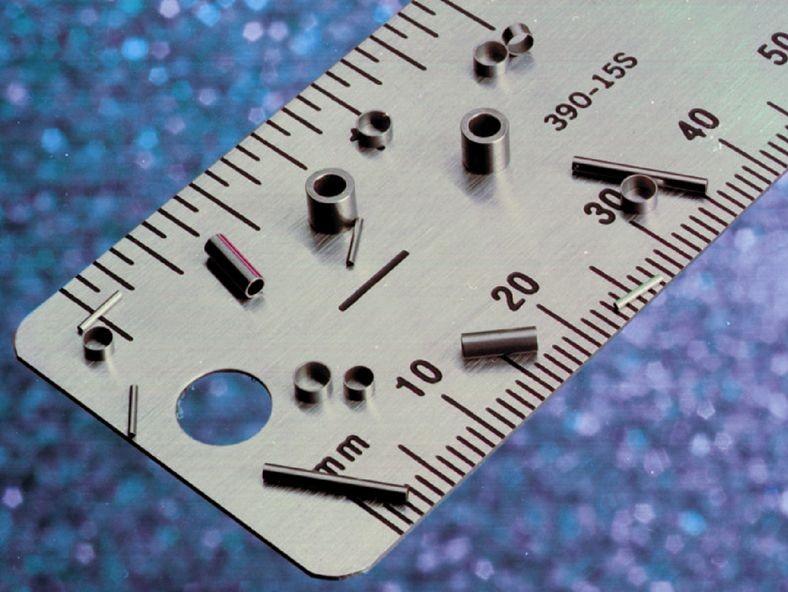

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services