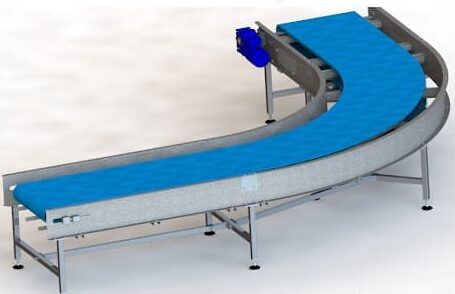

Belt Conveyors

Bulk Bag Handling

Industrial Dryers

Mixers & Blenders

Palletizers

Pneumatic Conveyors

Screw Conveyors

Vibratory Feeders

Weighing Systems & Scales

Bulk material handling systems are the backbone of industries that process and transport large volumes of raw materials. These systems are designed to efficiently move, store, and manage bulk solids such as coal, ores, grains, cement, chemicals, and aggregates. Whether it’s in mining, agriculture, construction, or manufacturing, bulk material handling plays a critical role in ensuring that materials flow smoothly and operations run reliably.

The core components of a bulk material handling system typically include conveyors, hoppers, silos, feeders, stackers, reclaimers, and dust control systems. These elements are engineered to work together seamlessly, minimizing material loss and maximizing throughput. Proper design and integration of these components are crucial for reducing downtime, improving worker safety, and maintaining product quality.

The bulk material handling industry offers both standardized and custom-engineered solutions, depending on the scale and complexity of the application. Conveyor systems are particularly essential, with belt, screw, drag, and pneumatic conveyors being selected based on the material type and operational needs. Storage solutions like silos and bins help in managing inventory, while feeders and valves regulate the flow of materials with precision.

Industries that rely on bulk material handling include mining and quarrying, cement and building materials, food and agriculture, power generation, and chemical processing. These operations require systems that are not only robust and durable but also adaptable to extreme conditions and varying material properties. Investing in efficient handling equipment leads to greater productivity, energy savings, and reduced operational costs.

As demand grows for faster, cleaner, and more sustainable material movement, the bulk material handling industry continues to innovate. Trends such as automation, real-time monitoring, dust suppression technologies, and environmentally friendly designs are shaping the future. Our comprehensive range of bulk handling solutions is built to support these evolving needs, helping customers optimize their operations from pit to plant.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

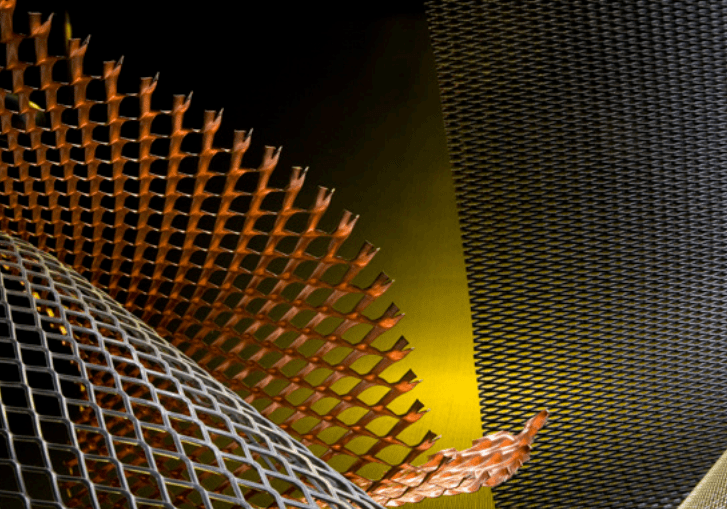

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

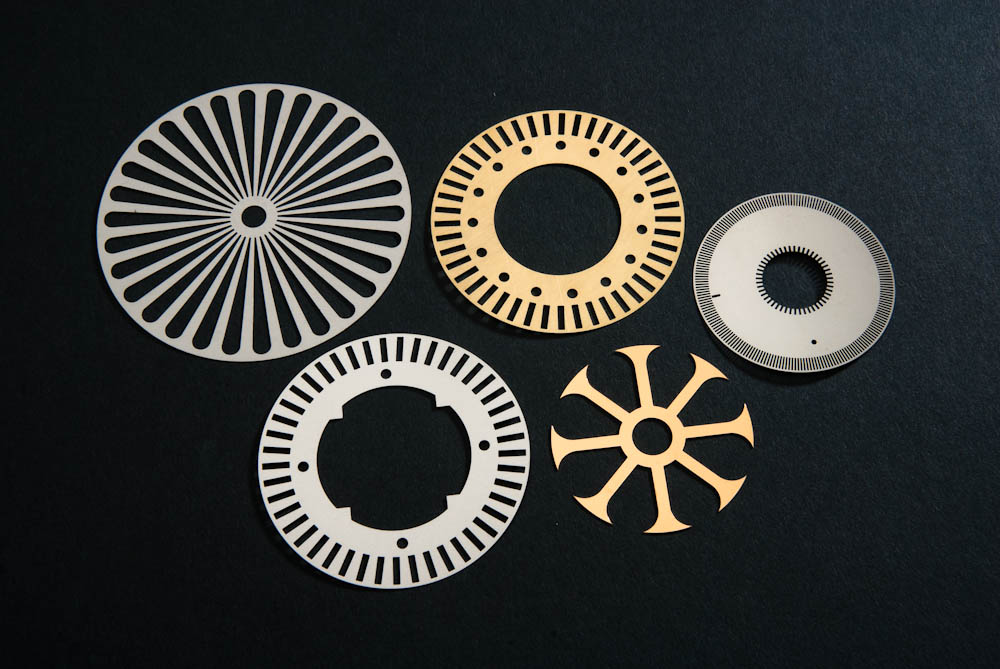

Laser Cutting Metal Etching

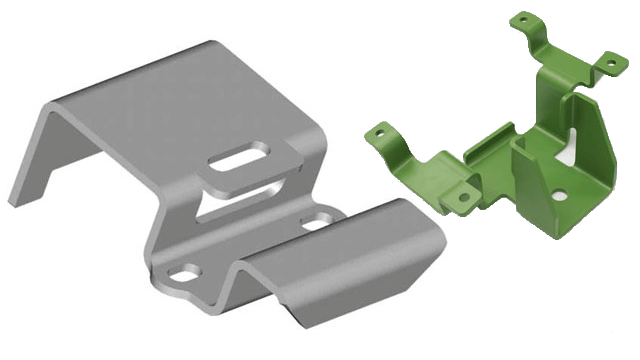

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

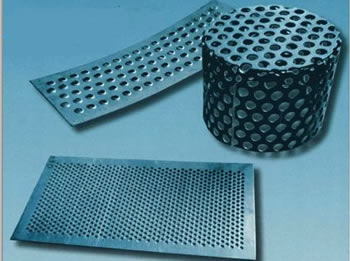

Metal Stampings Perforated Metals

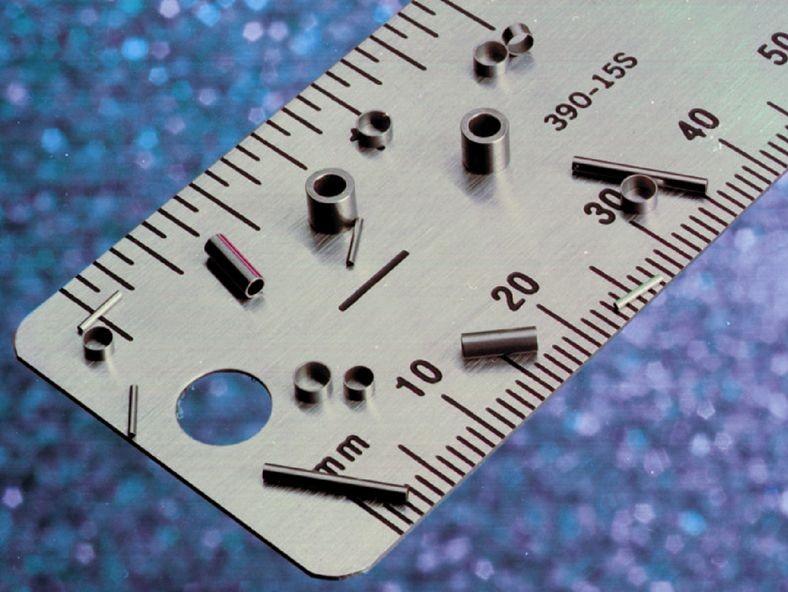

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

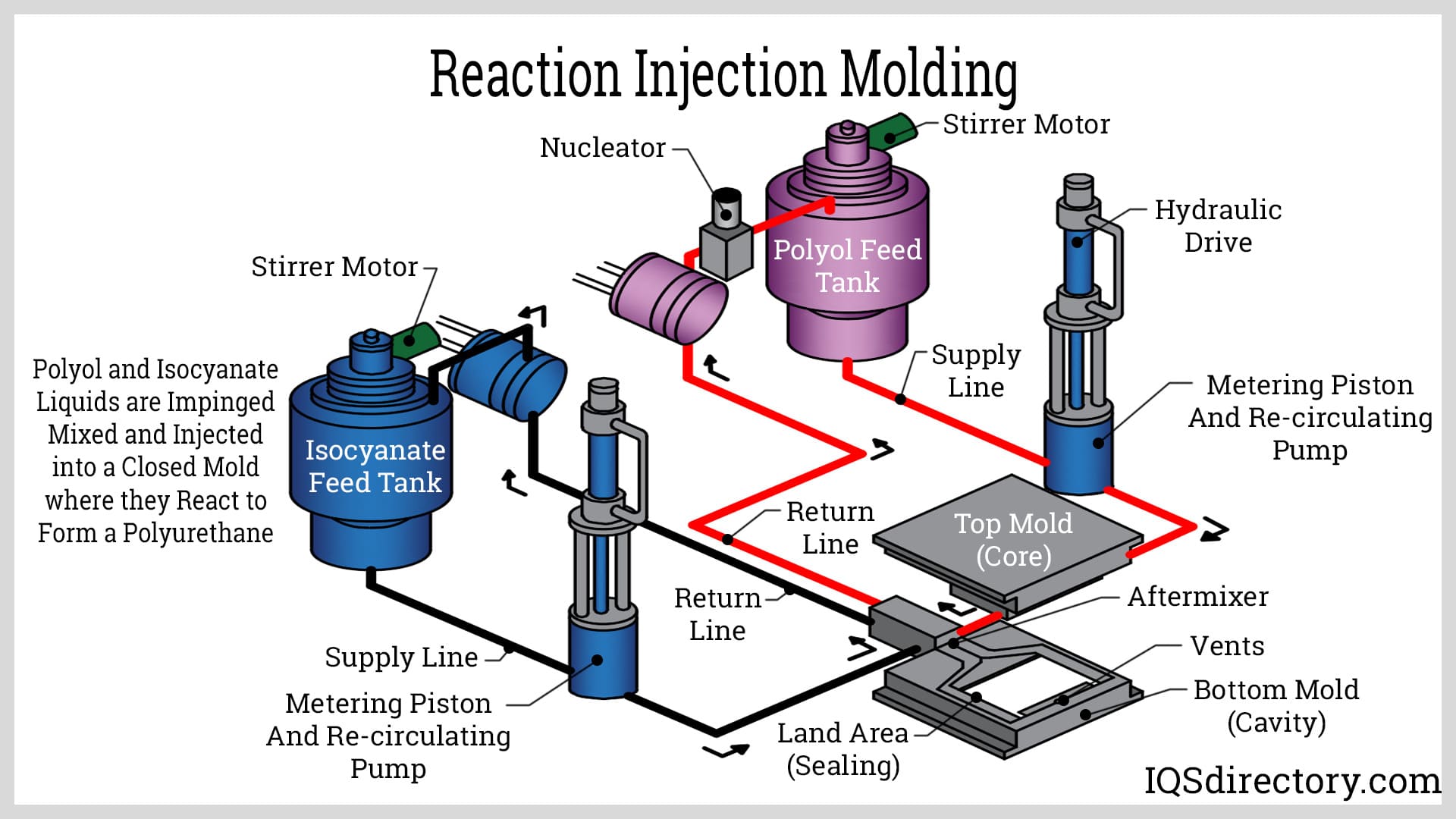

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services